Color Management

Lighting is all about standardized accuracy.

Lighting is all about standardized accuracy.

When an object is being observed by the human eye, its color is a result of the surrounding lighting conditions and the reflection of the object. Combined with the complex nature of the human eye, the slightest variation in lighting and environment can produce significant color difference. An object may appear entirely different in different environments. For industries that require consistent color appearance of the materials or products between all participants in the supply chain, the best way to guarantee that is to make sure that all colors are viewed in a strictly controlled environment that is built in line with industry standards. Therefore standards are required and thus established by respective industries for color viewing and color assessment.

Before the standard was established, every participant in the supply chain is using a different light source. Each was seeing a different presentation of the color when viewing the product. Now with the industrial standards, everyone is seeing the same color out of the product.

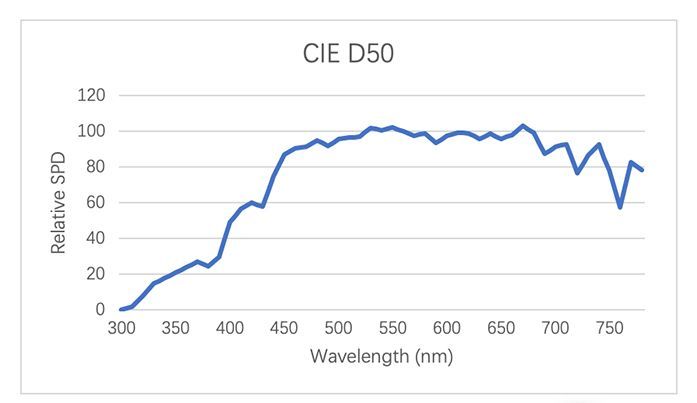

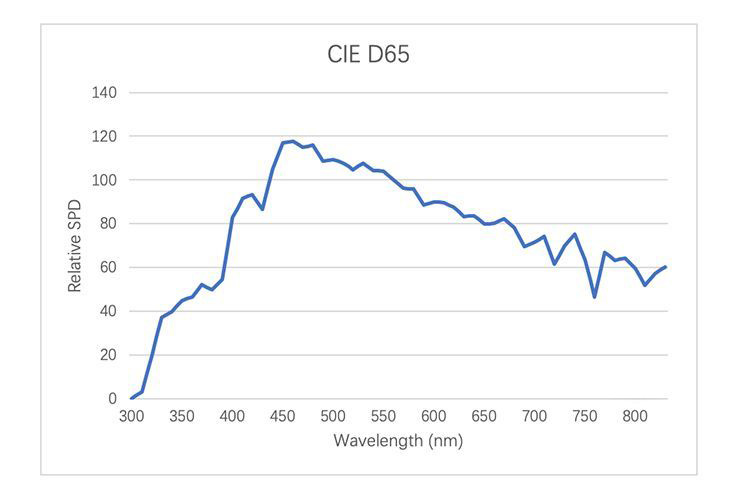

A standard illuminant is a theoretical source of visible light with a certain spectral power distribution. Standard illuminants provide a basis for comparing images or colors under different lighting conditions. The International Commission on Illumination (usually abbreviated CIE) has defined a number of standard illuminants to provide reference spectra for colorimetric issues. Illuminants A, B, and C represent average incandescent light, direct sunlight, and average daylight respectively. Illuminants D represent phases of daylight. For example, D50 has a CCT of 5003 K ("horizon" light), while D65 has a CCT of 6504 K (noon light).

Since D illuminants are based on the daylight curve that runs above the blackbody, D50 has a spectral energy distribution that closely matches that of a blackbody at 5000K. The printing and graphic arts industries have adopted ISO 3664:2009 “Graphic technology and photography– Viewing conditions” standard that specifies D50 daylight viewing conditions.

The standard regulates the viewing conditions for the color proofing of originals and reproductions in the printing and graphic arts industries. It specifies the requirements for color quality, light intensity, evenness of illumination, evenness, surrounding conditions and geometry. Differences in any of these aspects may have great impacts on the color observation and final appearance of the object. It helps engineers and manufacturers in the printing and graphic industries to design, evaluate, and certify their color viewing and assessing systems and helps reduce errors, control quality, and improve color communication.

The standard provides a specific spectral energy distribution between 300 nm and 780 nm for the D50 standard light source.

Metamerism describes the phenomenon that occurs when two materials or objects match under some lighting conditions but not under others. Industries dealing with textile, paint, automotive, plastics, packaging, and print may be affected by this when combining different materials or materials from different sources into one product. The Metamerism Index (MI) is derived by calculating the color difference of eight metamers (five in the visible spectrum and three in the ultraviolet range) in CIELAB or CIELUV. It tells how well the samples match under the test and reference illuminant. MI can be decomposed into MIvis (visible light) and MIuv.

Similar to D50, D65 refers to a standard illuminant of 6500 K, defined by ISO 3668 "Visual comparison of the color of paints". The standard describes all the parameters required to ensure color viewing and matching, such as viewing and ambient conditions. By definition, the CIE and ISO state that the “CIE standard illuminant D65 should be used in all colorimetric calculations requiring representative daylight, unless there are specific reasons for using a different illuminant.”

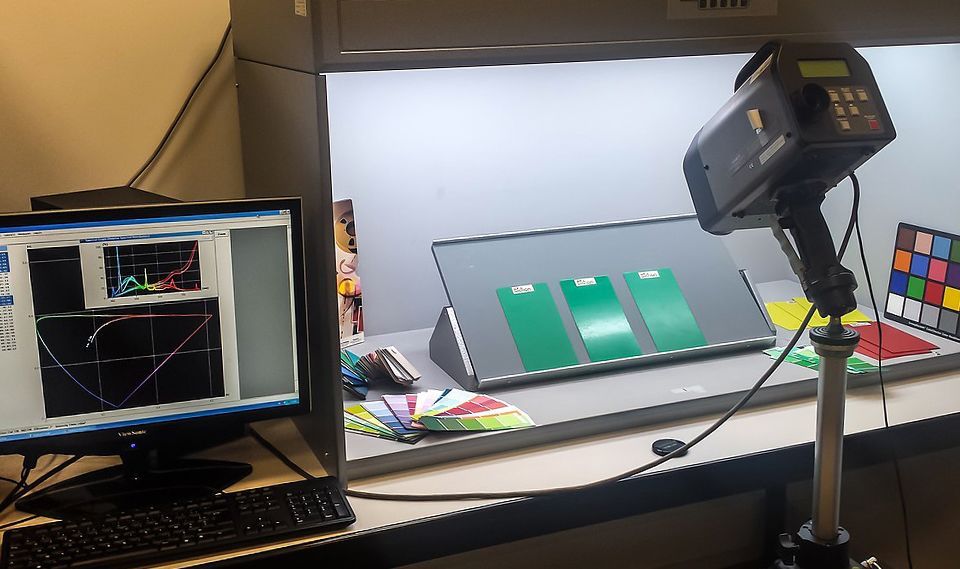

YUJILEDS developed its own line of standard lights for such applications that include color management as a significant process. Based on its expertise in LED recipe and custom design, it can create and provide the most accurate and consistent lighting conditions for color viewing and assessment that meet each specific industry standards. Whether it's for new material development, color matching, product evaluation and inspection, or quality control, our standardized lights can help present critical comparison between target appearance and reproduction, enable communications of colors between all the processes of production, increase consistency by removing the variable of lighting conditions, and improving customer experience by providing a professional atmosphere during reviews.

YUJILEDS standard illuminant series provides high CRI (>95), high reliability, ISO standard compliant performance, long lifetime, accurate consistency, form factor customizability, and compatibility with most color viewing facilities (e.g. color viewing booths) on the market.

Copyright © 2025 Beijing Yuji International Co., Ltd.