Custom LED PCB

Professional technical support on light design and creation.

Professional technical support on light design and creation.

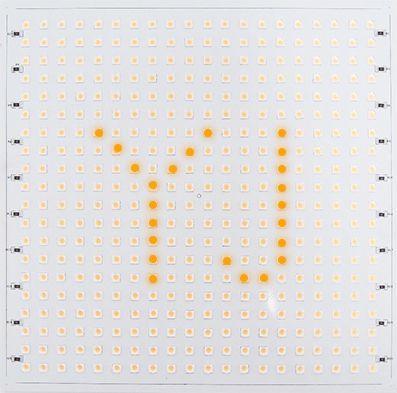

At present, SMD packaging type is the most widely used packaging form in LED lighting applications. Generally, the light emitted from a single LED component is very limited. Therefore, in order to fulfill sufficient light, multiple LED components would be used in a single light fixture.

Like other semiconductor devices, PCB is the best method to electrically connect the LED components. And a PCB with LED components soldered is usually called as “LED PCB”.

In addition to increasing the light output of the fixture by integrating multiple LED components, there are two more reasons which make the LED PCB be popular.

By integrating the LED components with different color temperatures or different colors into the same PCB, tunable color function could be easily achieved.

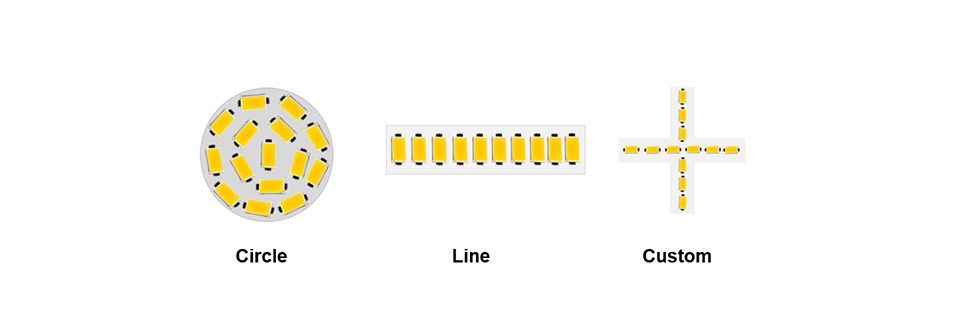

By using the PCB with different shapes, sizes and materials, diverse light fixtures could be realized to meet different lighting requirements.

From design phase to product finalizing, YUJILEDS offers customized printed circuit board design, fabrication and assembly services for a variety of LED applications. Regardless of the product development stage, we will quickly integrate our high CRI LED components into your designs.

We provide professional consulting and technical support to help you build your own light.

Our capabilities include FPC, FR4 and MCPCB.

| PCB Material | FPC | FR4 | MCPCB |

| Feature | • Flexible • Cost effective |

• Suitable for complex circuit design requirement • Excellent insulation property |

• High thermal conductivity |

| Typical application | LED Strips (LED Tapes) | Panel light | Panel light and linear light |

As per customers' requirements, any shape of LED PCB could be designed and tooled by YUJILEDS.

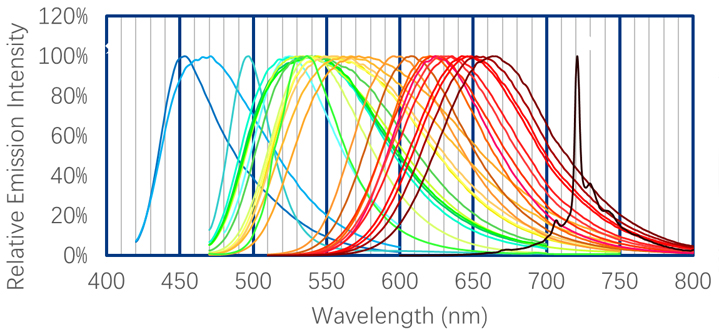

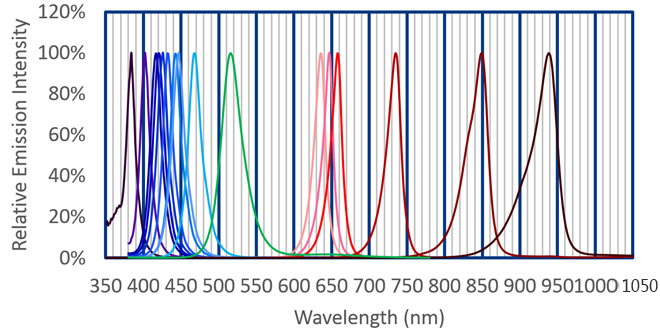

In the past few years, we have established good cooperation relationship with many famous LED chip manufacturers. We could easily source the LED chips with a full range emission wavelength from 360 nm to 850 nm. Based on our strong sourcing capability of LED chips, R&D capability of LED phosphors and experienced LED packaging capability, we could design & produce the light with any spectral shape which you desired. Read more about YUJILEDS spectrum customization technology.

Every LED package has its best use conditions and applications. We synthetically consider the design requirements on color temperature, luminous flux, luminous efficiency, beam angle, multicolor and cost to design your light.

• 2835: low power, cost effective

• 3030: small packaging dimension, high power, high luminous output

• 5730: high color stability

• 5050: multiple colors in one package, cost effective

• 5555: 60° beam angle, high thermal conductivity

• 7070: multiple colors in one package, high luminous output

There are many things we should take care when we design and build a LED PCB, these important things will affect the color quality, light output, efficiency, long-term stability and other performance of LED PCB.

In the most cases, several LEDs will be designed to work in series. Drive current for these LEDs is the same, but forward voltage for each LED is not. For example, the forward voltage of standard white 2835 LED in the market is generally ranged in 2.8 ~ 3.4 V at rated 60mA current. Therefore, a maximum 21% difference on power consumption of each LED will be generated if no consideration on voltage bin of the LED. This design will reduce the long-term stability of the LED PCB. Forward voltage bins and LED drive current can be difficult to manage in production. Whether you would like to implement a constant voltage or constant current topology, or are not sure, we can help. We handle current limiting resistor specification pairing, so that you can simply specify a constant voltage level and desired current draw. We ensure that each of our 0.1V bin-range LEDs will be used in a single panel or product, and ensure all of LEDs in a panel work at the same operating environment. This will greatly improve the long-term stability of the light fixture.

Based on preliminary information regarding expected ambient temperatures and required light output, we can provide recommendations on appropriate board materials, LED density, drive current and any heatsinking requirements. Once working prototypes have been built, we can provide ISTMT in situ temperature measurement test case and solder point temperature measurements, and provide TM-21 lifetime projections based on third-party LM80 test data that have been completed for our LEDs.

Looking for a high CRI, warm-white / daylight-white tunable circuit board design? Looking to maximize on lumens per dollar? Wondering if your LED density is sufficient, or if it might cause “spotting?” Need 1500 lumens per foot? Need 100 lumens per foot? We have you covered. Our experienced engineering team can provide recommendations and quickly provide schematic and design charts to optimize based on your requirements. We also have a variety of connector and other components to help integrate into power supply systems

Variation in LED chromaticity is sometimes a difficult issue. We recommend diagonal binning, which can reduce chromaticity variations to 50% - e.g. 2700K +/- 150K to 2700K +/- 75K, simply via strategic placement of SMD LEDs on a PCB. Rather than taking on the task of additional inventory and multiple reel variants per LED type, why not let us take care of this for you?

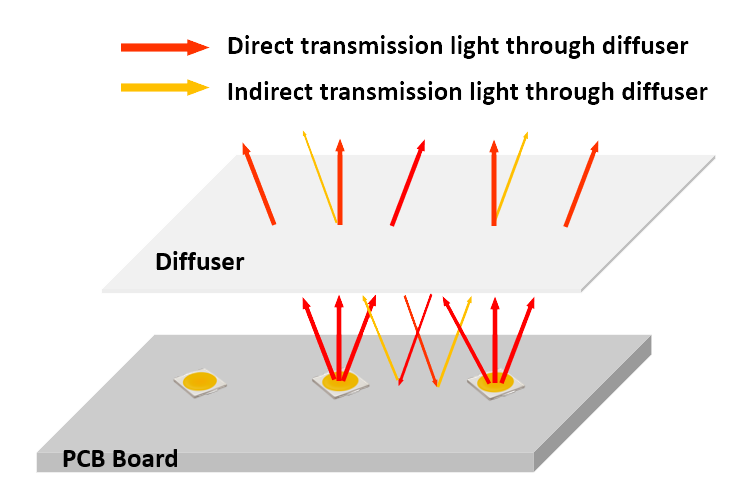

Light come from your fixture is a mixed light between direct transmission light and indirect transmission light. Generally, the color indirect transmission light is slightly different from direct transmission light due to inconsistent absorption characteristic against wavelength of the soldermask of the PCB board. Therefore, if you need the accurate light from the fixture, the absorption characteristic of the PCB board, even diffuser must be considered. With YUJI’s professional custom spectrum technology, we can easily help you to improve the color accuracy at LED level avoiding the work of finding right PCB board or diffuser.

Inform us usage purpose, place, shape, size, power consumption, luminous flux, luminous efficiency and other specific specs requirements.

Evaluation and work out a best solution with design files, target specification & quotation for customer's confirmation and approval.

Approve us to producing prototypes

Prototype production and make the inspection report

Prototype confirmation

Work out the specification & quotation for mass production

Approve us to start mass production

First batch mass production and make the inspection report

First batch porduct confirmation report

Product development success

Inform us usage purpose, place, shape, size, power consumption, luminous flux, luminous efficiency and other specific specs requirements.

Evaluation and work out a best solution with design files, target specification & quotation for customer’s confirmation and approval.

Placing order of prototype.

Prototype production and inspection report submission.

Prototype confirmation.

Work out the specification & quotation for mass production.

Placing order of first batch production.

First batch production and final specification determination.

First batch product confirmation.

Product development completion.

Copyright © 2026 Beijing Yuji International Co., Ltd.