Custom LED PCB

Professional skills and experience in LED PCB design

Request a PCB quote

In 2020, Yuji start to establish a brand new CUSTOM PCB business structure. In this business, Yuji will give all-round support to customers from following four aspects.

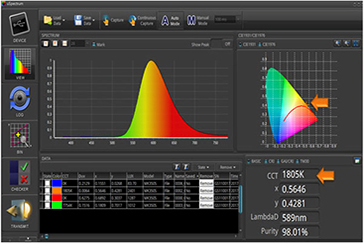

Nakamura Yuji, one of the subsidiaries of the Yuji Group, is a joint venture with investment from Mitsubishi Chemical to develop and produce best quality LED phosphors. Nowadays Yuji is one of the very few LED companies in the world that has more than 93 phosphors manufacturing capabilities. Yuji has the top spectrum simulation technology based on its LED phosphors expertise.

In PCB assembly, the light source will not only be limited to the LED manufactured by Yuji. According to the needs of customers, Yuji light source and light sources from other brands can be integrated to provide high performance and more suitable solutions for customers.

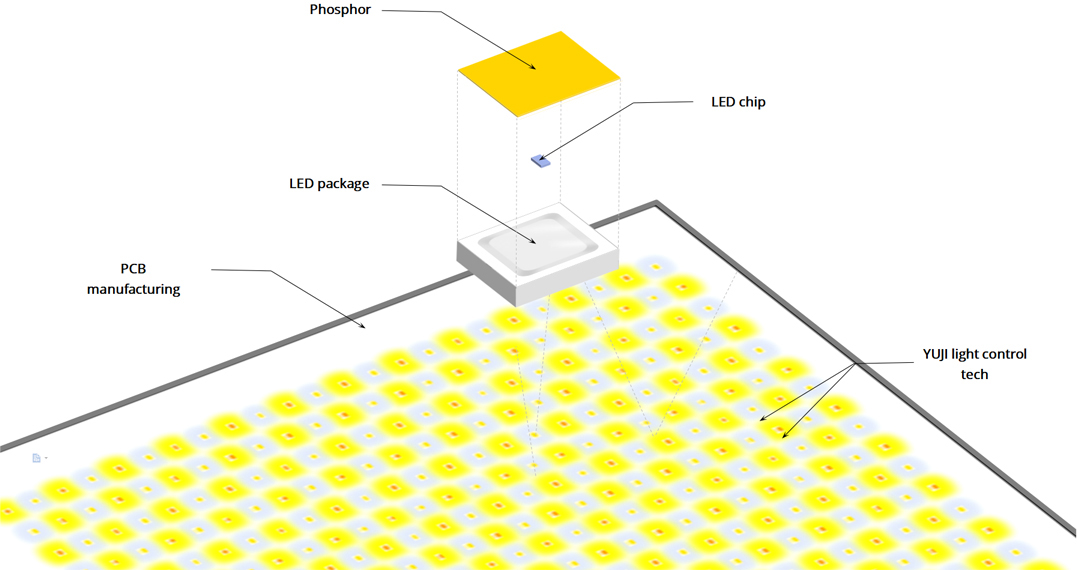

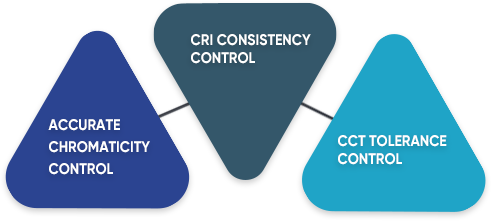

In PCB business, Yuji will completely focus on the performance of light in the entire board rather than a single LED. Based on Yuji LIGHT CONTROL TECH, the light quality of a whole board could be more accurate than a single LED.

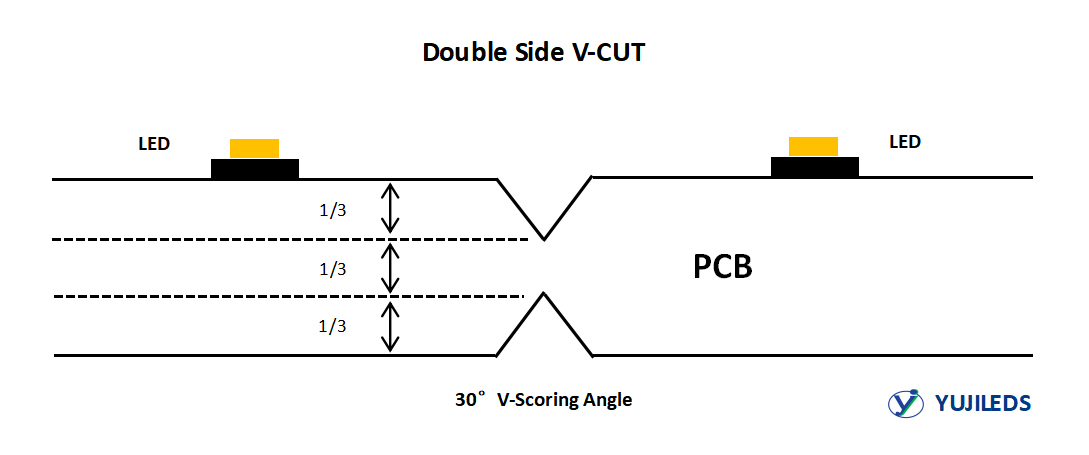

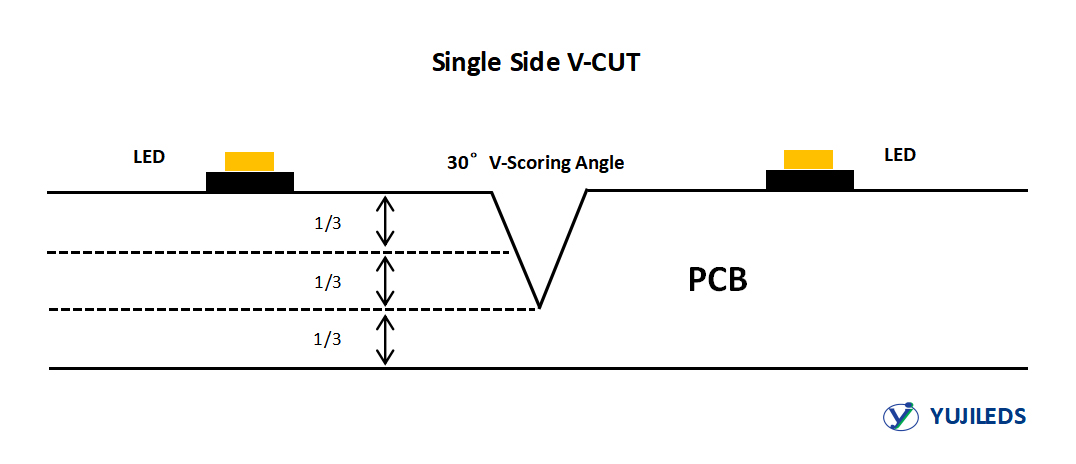

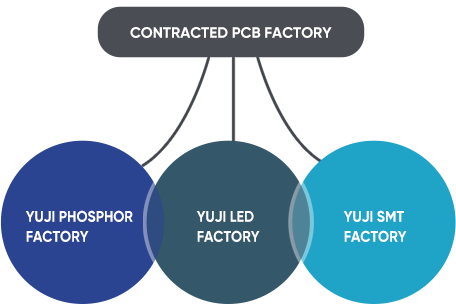

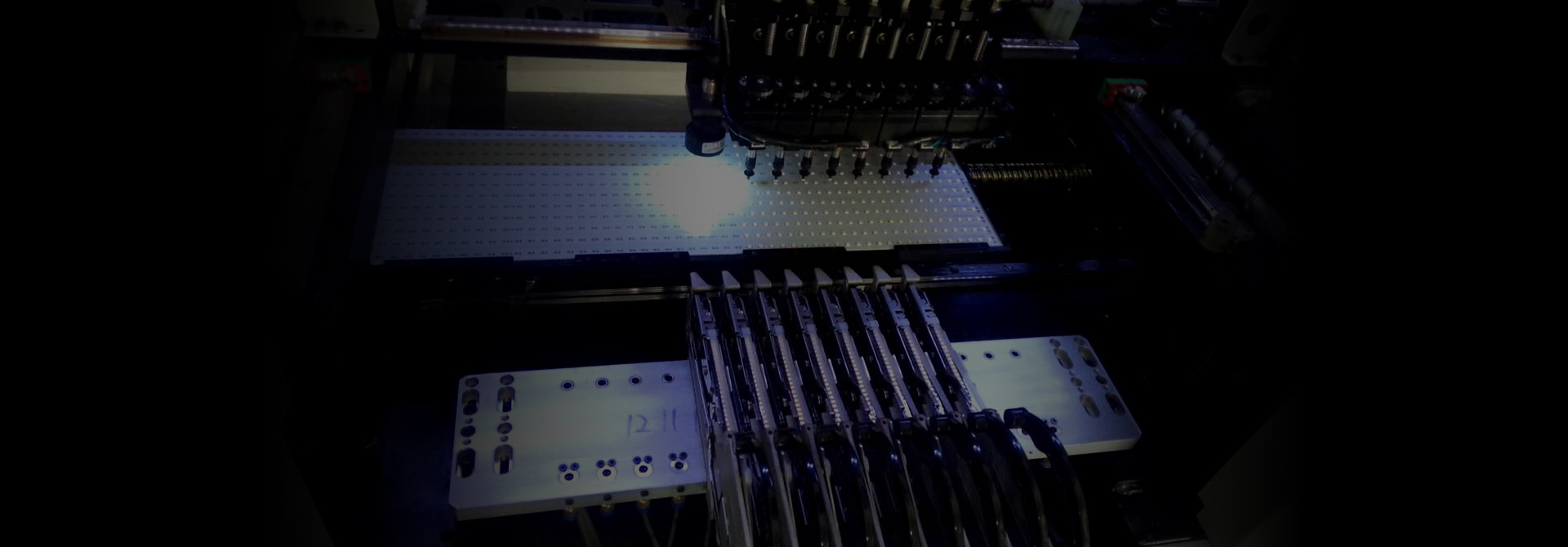

In PCB manufacturing, Yuji owned its phosphor factory, LED factory, SMT factory and have contracted with PCB factories to provide customers with high quality LED boards with strict standards of production and quality control.

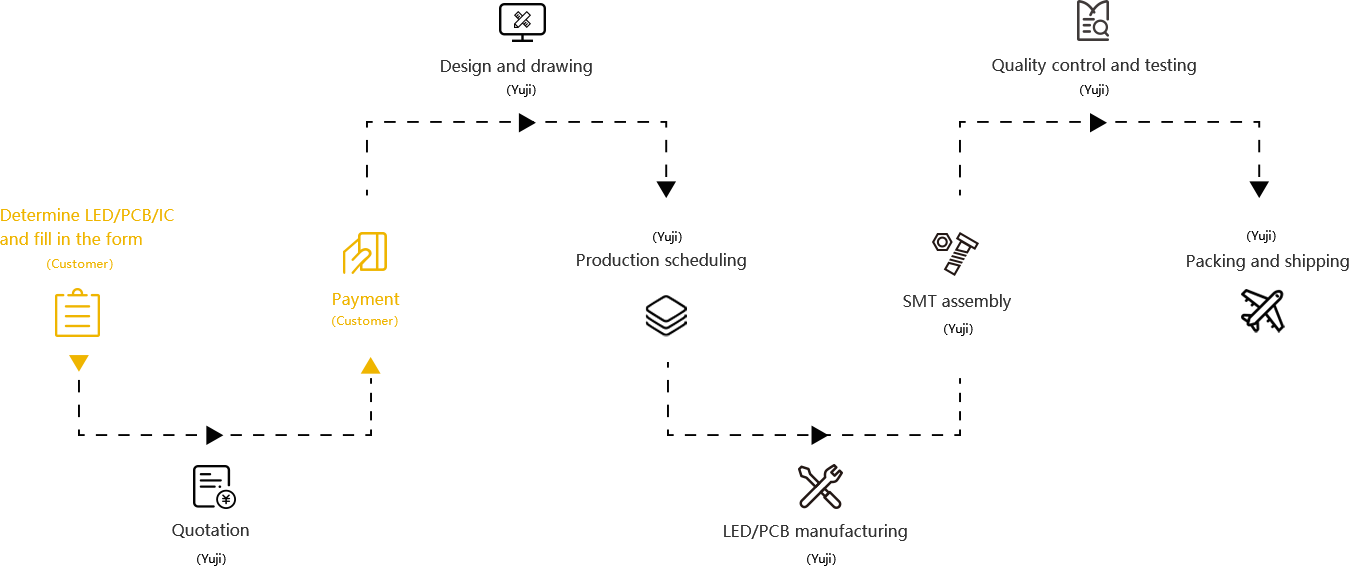

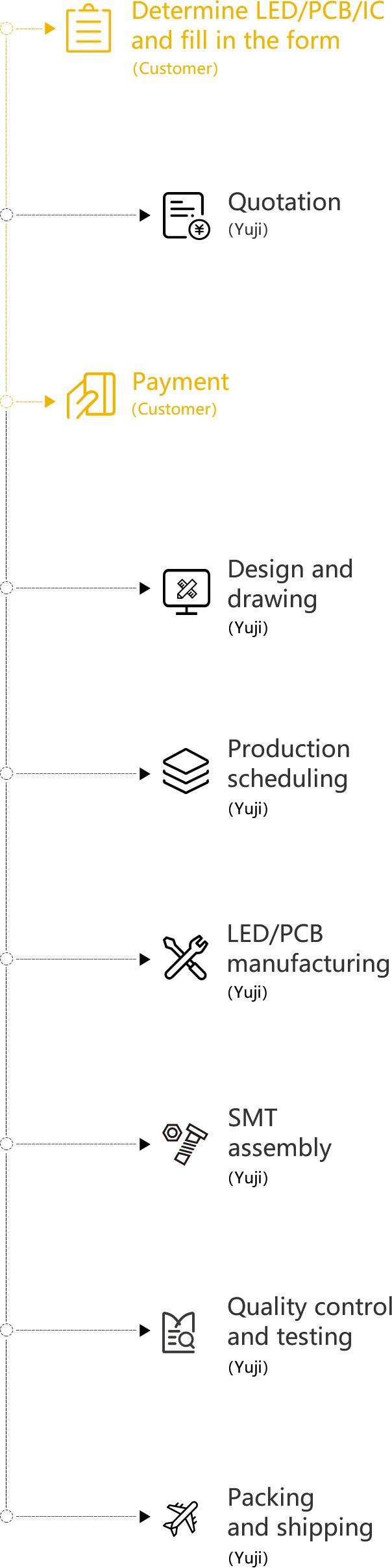

STEPS to easily make PCBs. Customers will only need to determine the specs and our team will assist you with the rest.

The total period from inquiry to delivery will take 3-6 weeks, which depends on the specialty and difficulty of the PCB design.

Circuit drawing & designing

PCB boards / LEDs manufacturing

SMT

Testing & packaging & transporting