Flip Chip COB

High lumen density COB solution by YUJILEDS.

High lumen density COB solution by YUJILEDS.

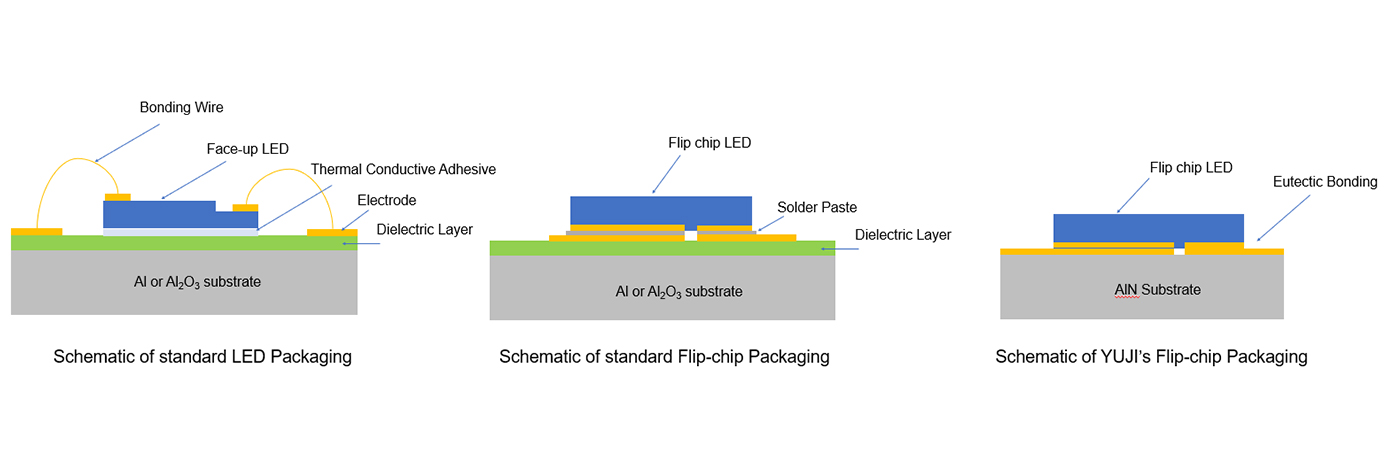

Difference on LED packaging structure

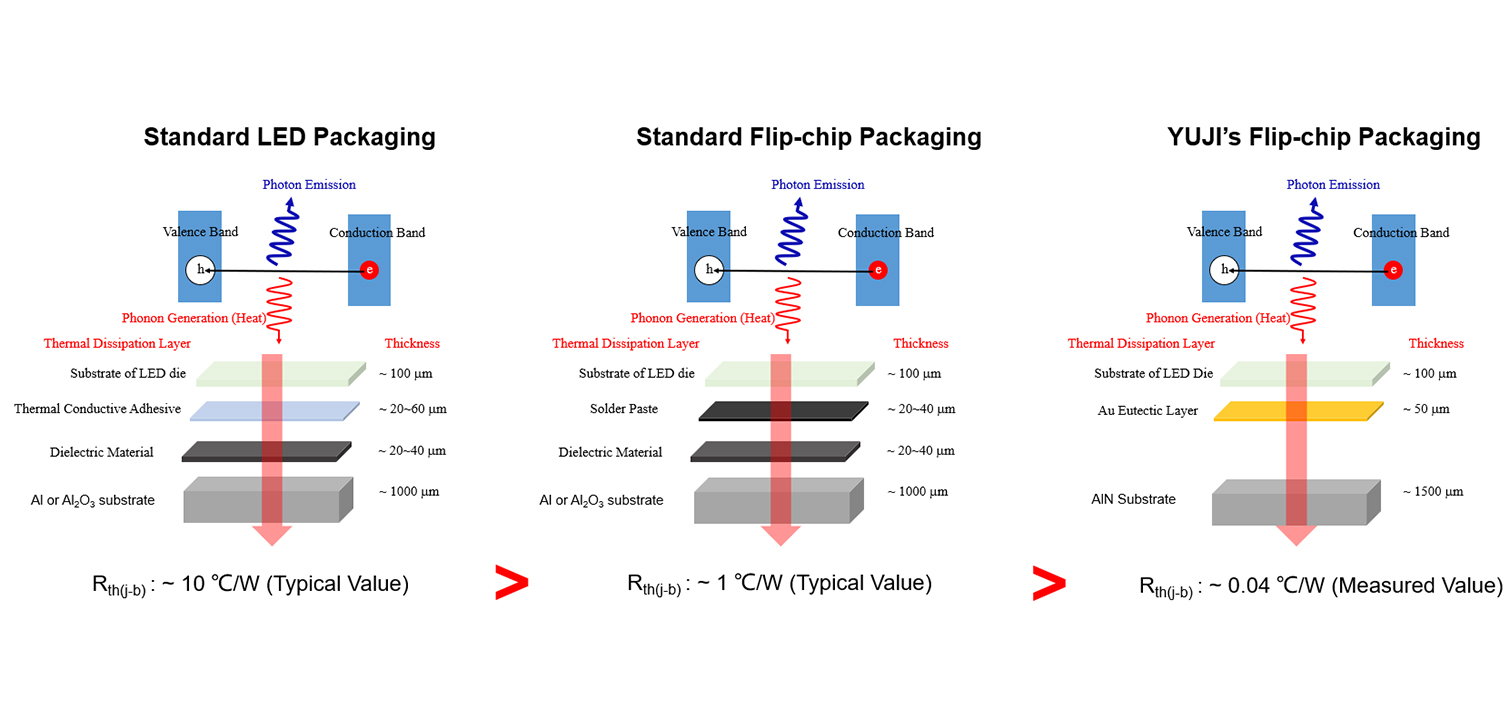

Improving the thermal conductivity by reducing the heat dissipation path

Comparing with standard face-up LED packaging technology, wire bonding has been avoided in YUJILEDS flip chip packaging technology, thus no risk of gold wire breakage.

Comparing with standard flip chip packaging technology, eutectic bonding between LED chip and substrate in YUJILEDS flip chip packaging technology result in excellent thermal conductivity for this whole device.

The flip chip structure of the COB transfers the heat directly to the substrate, so the efficiency can be largely increased.

The AlN substrate of the COB has a heat transfer efficiency as high as about 300 W/(m•K), twice of Al substrate, and six times that of Al2O3 substrate.

Easier optical design: smaller LES means easier secondary optical design, makes more compact and portable light fixture realizable.

Less manufacturing cost: less BOM and manufacturing cost should be used in more compact light fixture.

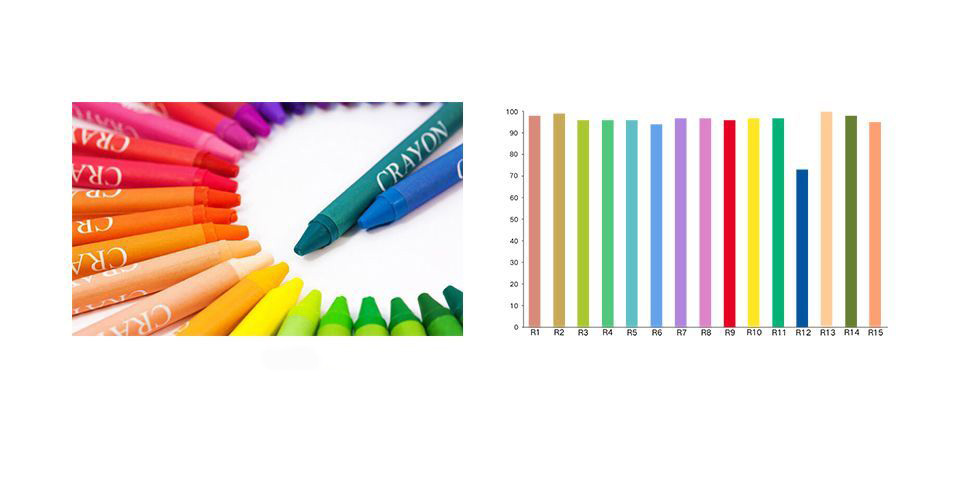

With reliable phosphor properties, appropriate mixing ratio and the unique packaging process technology, this COB has a CRI (Ra) as high as 95 even at a CCT of 5600K.

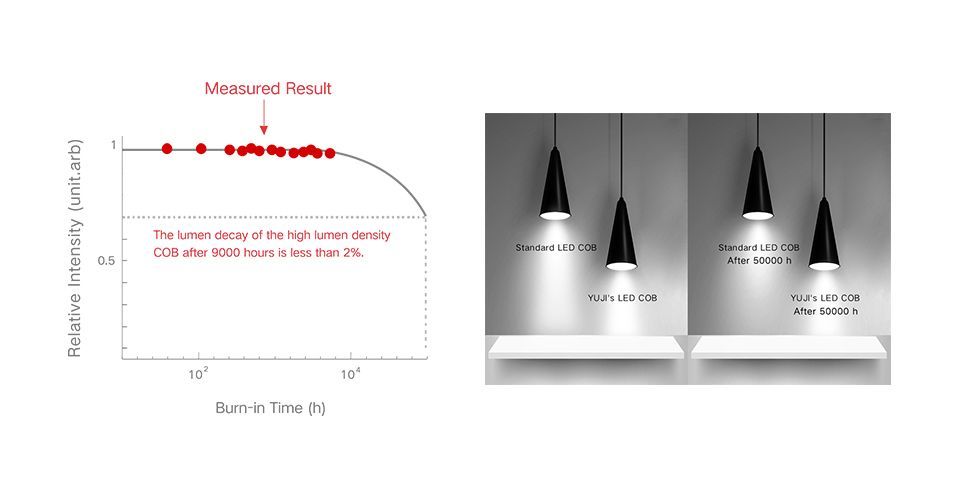

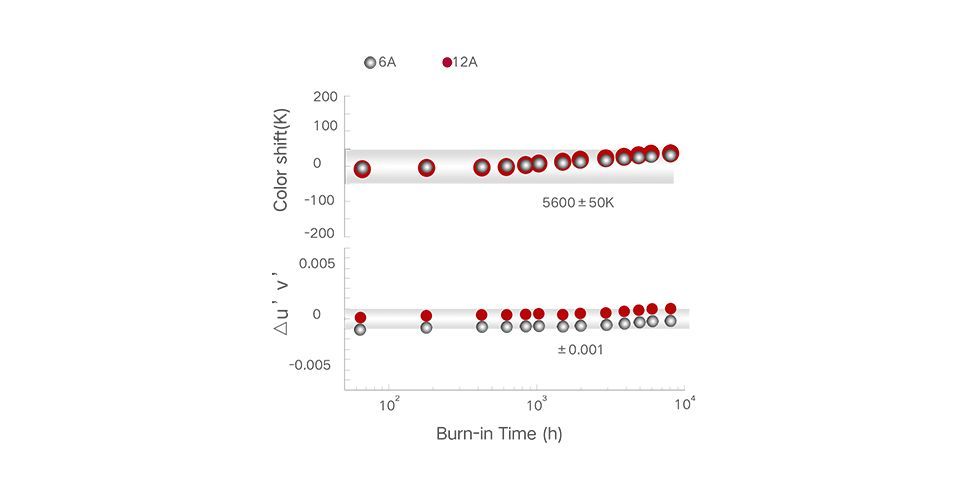

The maintenance rate of the initial lumen flux of the high lumen density COB at 12 amperes drive current is more than 98% after 9000 hours continuous light up.

The high lumen density COB shows a color temperature shift smaller than +/-50K after 9000 hours and the chromaticity shift from black body curve is less than +/-0.001.

A chip on board (COB) light source has a small light emitting surface (LES) and large luminous flux, thus it is usually used in directional lighting fixtures. However, keeping a COB small is extremely challenging, because the compact arrangement accelerates heat accumulation and compromises the performance. Therefore when designing a COB, it is always the key point to improve the luminous flux and the reliability while controlling the LES.

Based on this principle, YUJILEDS high lumen density COB was developed, the world's highest lumen density LED.

Stage lighting

Horticultural lighting

Sport lighting

Inspection lighting

Copyright © 2026 Beijing Yuji International Co., Ltd.