Glass / Ceramic

What is PiG / PiC?

White LEDs (WLEDs) have become a conventional light source these days due to its high luminous efficacy and long lifespan compared to traditional fluorescent lamps. A white LED normally consists of a blue or violet chip and phosphor that converts the narrow band emission of the chip to a broader spectrum. Conventionally, the phosphor is mixed with organic or silicone resin so that it could be mounted on top of the LED chip, however, the defects of thermal and chemical stability of the binders cannot satisfy the recent development of high-power WLEDs.

To overcome the inherent defects of the resin substrates, there are many inorganic alternatives to the resin-based phosphor, such as phosphor ceramics, bulk glass phosphor, and single-crystal phosphor. Among them, Phosphor in Glass (PiG) and Phosphor in ceramic (PiC) are more practical and promising solutions due to their relatively simple manufacturing process and advanced photonic characteristics like color conversion efficiency compared to other solutions. PiG is manufactured by sintering the mixture of phosphor and glass powder to glass plates at atmospheric pressure with a temperature of less than 800°C. And to make PiC, it is necessary to directly calcine the mixture of Phosphor and ceramic matrix powder at more than 1000°C. By replacing resin, PiG and PiC improve the performance of thermal and chemical stability, which gives it the potential for high-power WLED applications. In addition, PiG and PiC provide a homogeneous distribution of phosphor particles in the substrate where the nonuniformity is caused by the viscosity of resin. Thus, PiG and PiC have huge potential in various applications in the near future.

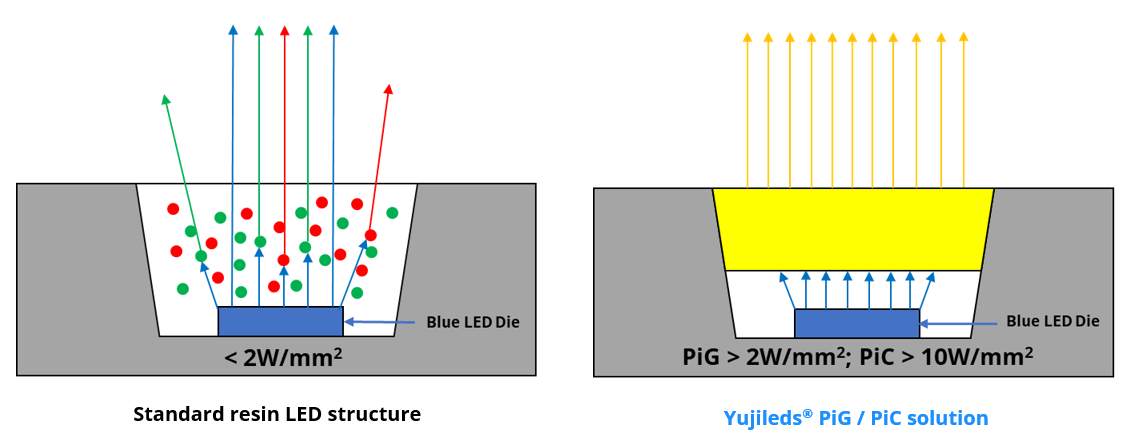

Why Change from Resin to Glass?

Normal white LEDs use red and green phosphor mixed with silicone, epoxy, or other resins. The mixture is cast onto the chip to convert the blue light emitted from the chip into red and green light. Although this approach is simple to prepare, it has some defects, resin is susceptible to heat and water and the nonuniformity distribution of phosphor particles affects the chromaticity of output light. PiG and PiC, on the other hand, are usually solid films, which can be cut to fit the shape of an LED chip perfectly. In addition, the phosphor particles are dispersed more homogeneously than phosphor in resin and thus the chromaticity and spatial distribution of the converted light are near perfect. The glass is also more stable than resin to protect phosphor from the damage of heat and water vapor.

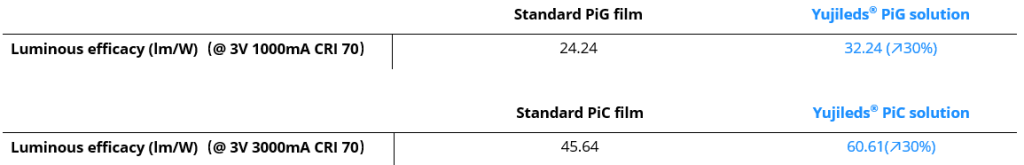

30% higher luminous efficacy than average

Because Yuji has the ability to produce phosphor, we have phosphor with excellent thermal stability. PiG / PiC need to go through a high-temperature sintering process, and good thermal stability prevents phosphors from changing during the production of PiG/PiC. As a result, the Yujileds® PiG / PiC products have a luminous efficacy far exceeding the industry average. Under the same power density, the luminous efficacy is 30% higher than other products in the industry.

Yujileds spectral quality ensurance

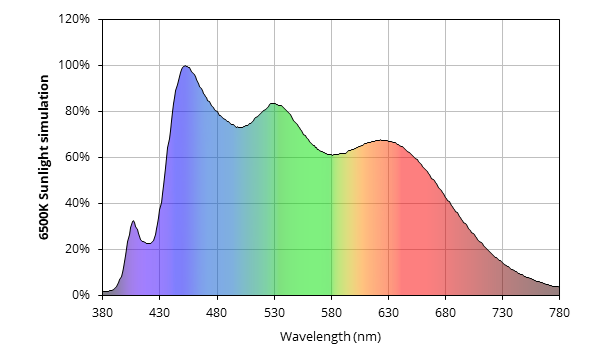

Sunlight simulation

Based on Phosphors technology of Yujileds®, we can have a variety of phosphors covering the visible light range. We can select phosphors with good thermal stability and make them into PiG film. It is possible to produce a simulated sunlight light source with high power density with a suitable light source.

High CRI LED lighting

For light sources around 450nm, we can have more Phosphors to choose from. Therefore, unlike the common PiG film with CRI>80, we provide a solution with CRI>95 for selection. The introduction of Yujileds® High CRI Technology has undoubtedly brought about brand-new changes under high-power-density lighting, and it will bring vivid colors to more scenes.

Customized spectrum design

Of course, we provide more than just white light. In special scenarios, other colors also have huge applications. We have rich experience in the production of mixed phosphors, and can reproduce any color that exists in CIE1931. We also summarize these experiences into data and reflect them in our Spectrum Design System (Pro). Customers can use this system to simulate the preliminary feasibility of the product.

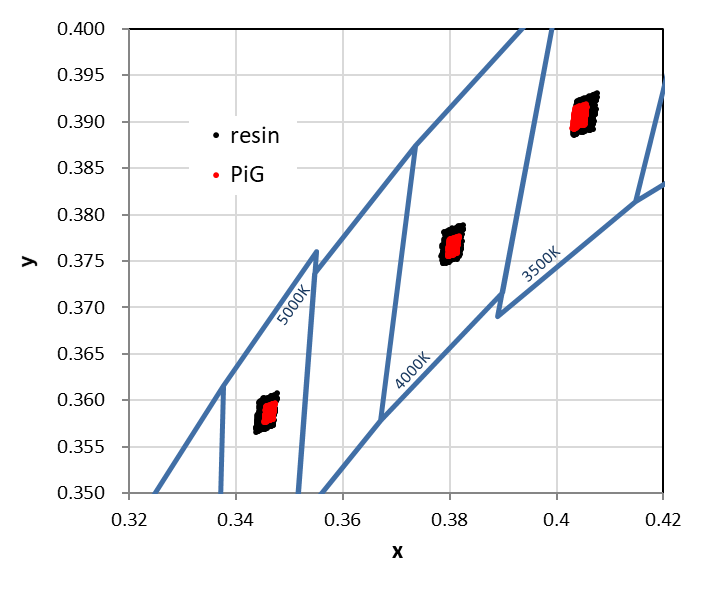

Accuracy spectral and chromaticity match with excitation light source

Due to the characteristics of PiG, the light emitted by the same PiG under different lights of different power LED chips or laser will have a large shift in CIE 1931. Therefore, in order to achieve accurate color control, Yujileds® will customize the PiG film that matches the light source of the customer. At the same time, due to the homogenous distribution of the phosphor particles in PiG, Yujileds® PiG solution can bring more concentrated chromaticity coordinates, and thus the color of the emission light is more accurate. The color deviation is small enough for omitting the binning process.

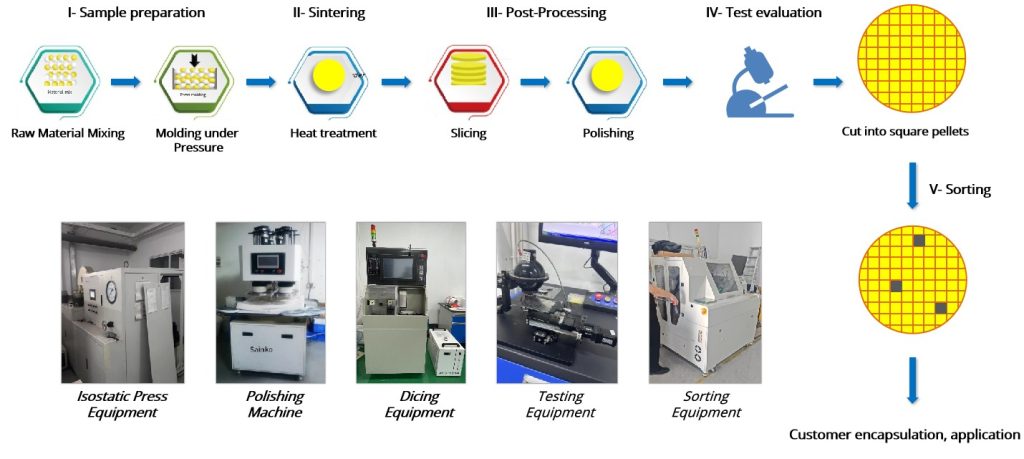

Yujileds manufacturing and testing capabilities

At Yujileds, we offer end-to-end manufacturing and testing capabilities for both Phosphor in Glass (PiG) and Phosphor in Ceramic (PiC) solutions. Our production process begins with the phosphor materials themselves — carefully selected for optimal emission wavelength and particle size according to specific application requirements. This ensures precise control over performance from the very first step.

Our full in-house production includes slicing, polishing, inspection, cutting, and final grading. This vertically integrated process enables us to deliver high-quality products with speed and consistency.

Thanks to our comprehensive capabilities, we can flexibly customize color coordinates, dimensions, and thicknesses to meet your exact specifications. Whether for prototyping or large-scale production, we provide responsive, precision-engineered solutions.

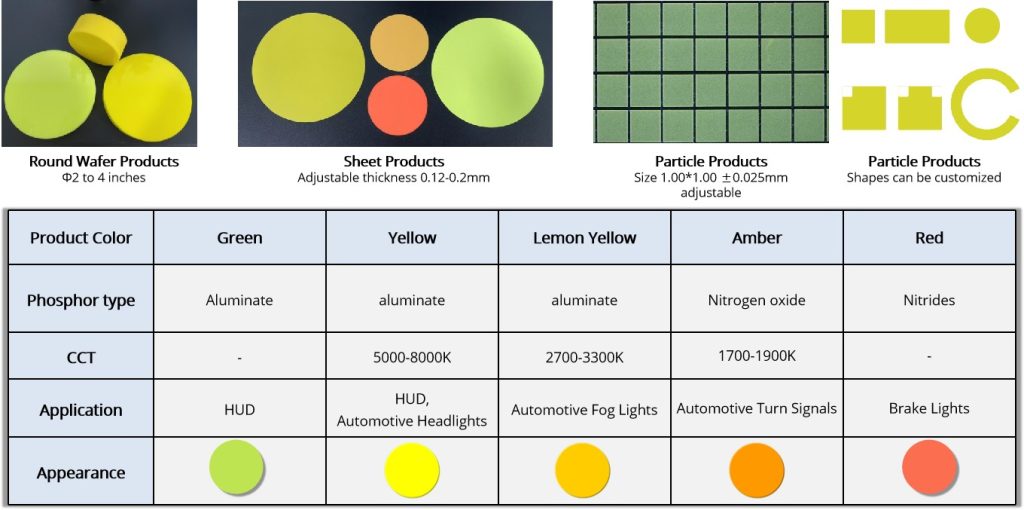

Products for automotive lighting

Yujileds offers a comprehensive range of Phosphor in Glass (PiG) products, primarily designed for automotive and projection applications. Our PiG solutions are engineered to perform reliably across a wide range of demanding use cases, including automotive headlamps, heads-up displays (HUD), turn signals, and brake lights.

With high thermal stability, precise color control, and customizable specifications, our PiG products are tailored to meet the rigorous requirements of modern lighting systems.

More than PiG / PiC

Phosphors on sapphire or aluminum

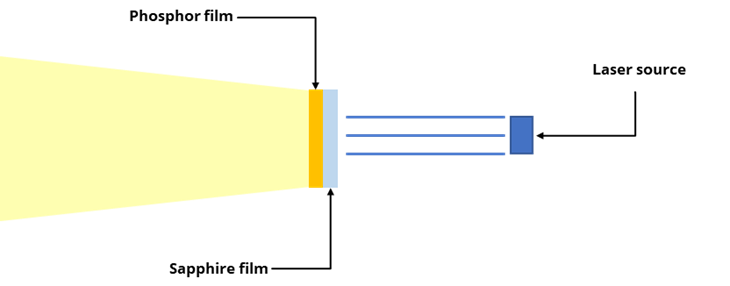

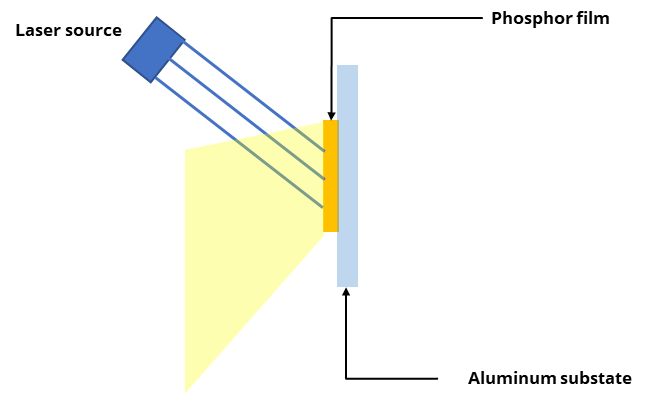

Since the light-emitting surface of the laser is small, it is easy to make high power, so it will bring extremely high-power density. The usual solution is to rotate or move the phosphors film (PiG or PiC) but adding a movable device in the light path will undoubtedly increase the volume of the light source module and reduce the reliability.

Yujileds® brings phosphors on sapphire and phosphors on aluminum. Due to the good thermal conductivity of the sapphire or aluminum substrate, the heat concentrated at one point is well dissipated, thereby avoiding the destruction of the phosphors composite material by excessive heat.

Available for different optical path options

Generally, the laser light source often adopts the design of remote fluorescence, so two different optical path designs of transmission type and reflection type have also been produced. Yujileds® can provide two different substates, sapphire and Aluminum, to meet the needs of customers for optical path design.