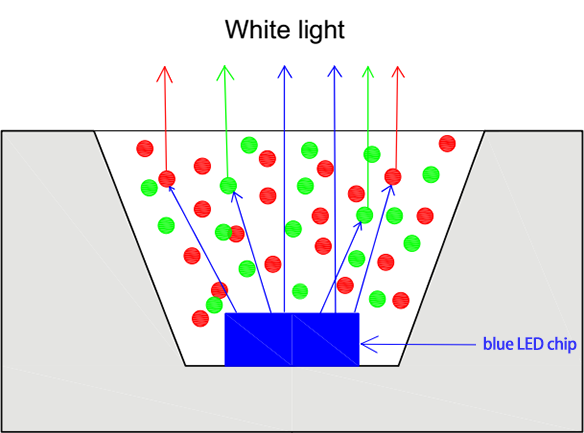

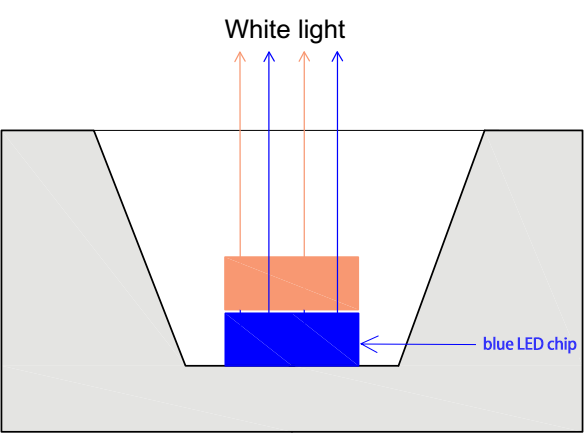

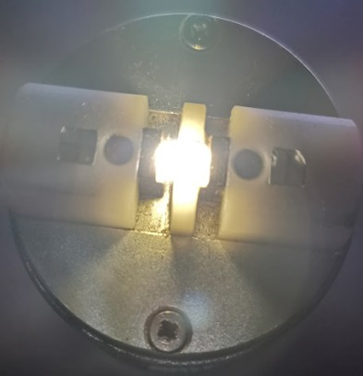

Phosphor in Glass (PiG)

A new product from Nakamura Yuji

Yuji brings its mature phosphor technology to the remote phosphor field.

Yuji PiG shows high performance and versatile in every aspect.

| Uniformity | < 500K |

| Glass transition Temperature (Tg) | 650~850K |

| Thermal Expansion Coefficient | 8~17 ppm/K |

| Thermal Conductivity | 1.01~3.44 W/m*K |

|  |  |

| Rectangle (1mm * 1mm and above) | Round (Ф1.5mm and above) | Exotic |

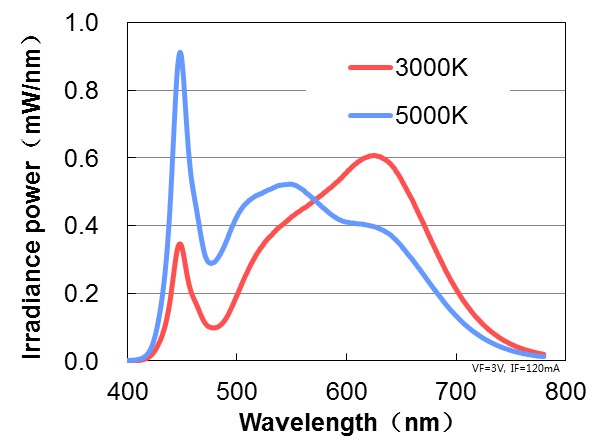

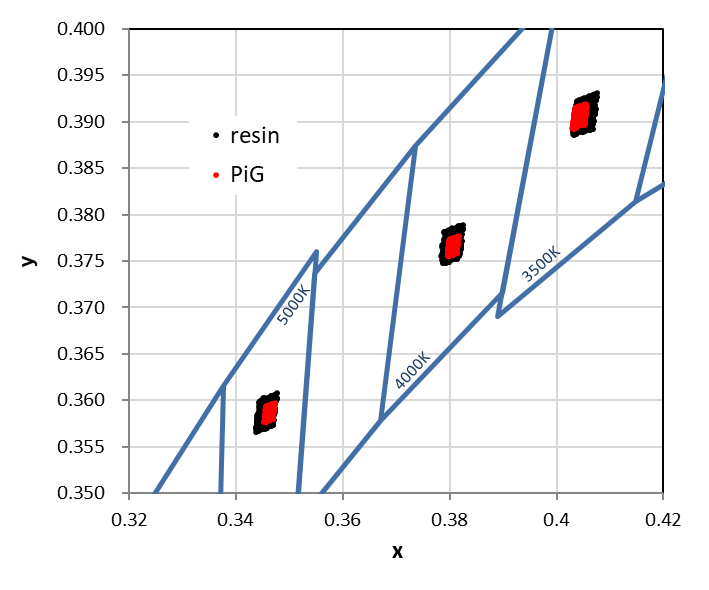

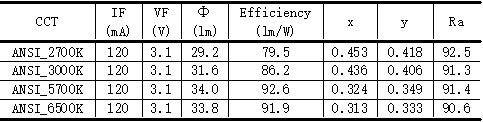

| CCT | IF (mA) | VF (V) | Φ (lm) | Efficiency (lm/W) | x | y | Ra |

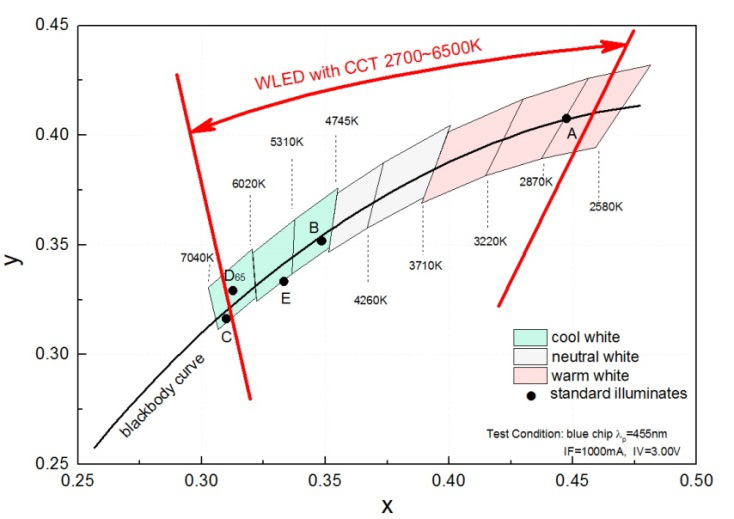

| ANSI_2700K | 120 | 3.1 | 29.2 | 79.5 | 0.453 | 0.418 | 92.5 |

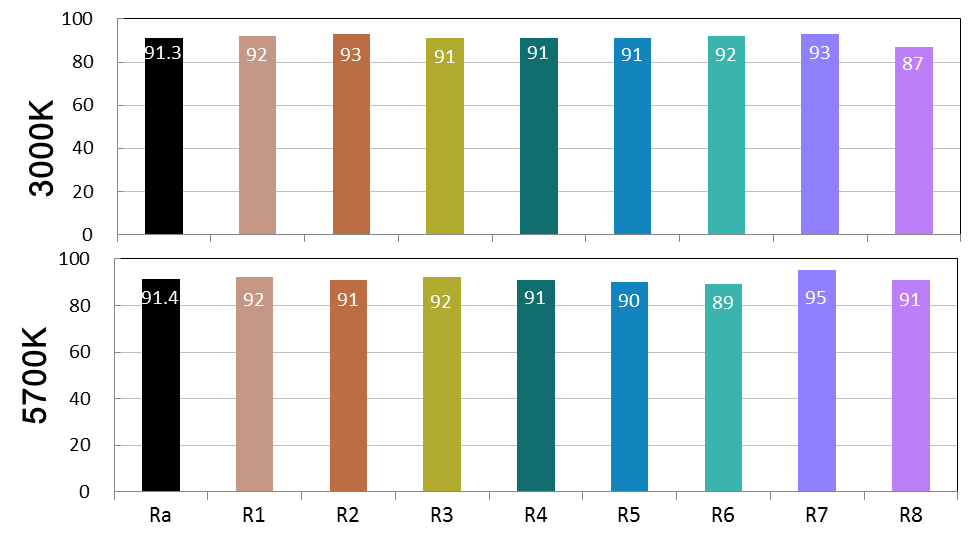

| ANSI_3000K | 120 | 3.1 | 31.6 | 86.2 | 0.436 | 0.406 | 91.3 |

| ANSI_5700K | 120 | 3.1 | 34.0 | 92.6 | 0.324 | 0.349 | 91.4 |

| ANSI_6500K | 120 | 3.1 | 33.8 | 91.9 | 0.313 | 0.333 | 90.6 |