A Deep Tour on LED Phosphor Part III: Performance of Phosphor Based LEDs

The Parameters of LED Device

1. Luminous Flux and luminous efficacy

LED luminous flux is the amount of light emitted per unit time, and LED luminous efficacy is the LED luminous flux per unit power. They both indicate the luminous intensity of LED devices, which is an important parameter for the luminous performance of the LED devices. However, they are used on different occasions. For applications require high illumination, the luminous flux (absolute value) is important; while for high performance areas, it demands high light efficacy.

2. Color Gamut

The color gamut is the range of light colors that LED devices can achieve. With larger gamut, the LED devices can achieve more amounts and more saturated color. Taking the display field as an example, the early TV sets were only black and white with a small color gamut. As the technology development, the cathode ray display could express 72% of NTSC color standard and LCD is 90%. Now the mainstream LED backlit display has a number of 105%. The latest quantum dot display technology can increase the color gamut value to over 110%. However, it has the disadvantages of high cost, high toxicity, and low yield, and thus currently cannot dominate the market. In 2018, Beijing Yuji Xinguang Optoelectronic Technology Co., Ltd. increased the gamut value to the level of quantum dot technology based on GaN blue chip + nitrogen oxide (β-Sialon) green phosphor + silicon fluoride (KSF) red phosphor and other auxiliary materials, taking the lead in the field of backlit technology.

3. Color rendering index

A color rendering index (CRI) is the quantity describing the degree of differences between the color of an object perceived by human eyes under the sample light source and that under a standard light source (sunlight) with the same CCT. The value is up to 100 and could be negative. A higher CRI indicates the sample light source rendering the color more similar to the standard light source and thus is considered to have better light quality.

a. Average color rendering index(Ra)

The average of CRIs using the first eight test color samples specified in CIE (1995).

b. Special color rendering index

The CRI of the last six test color samples.

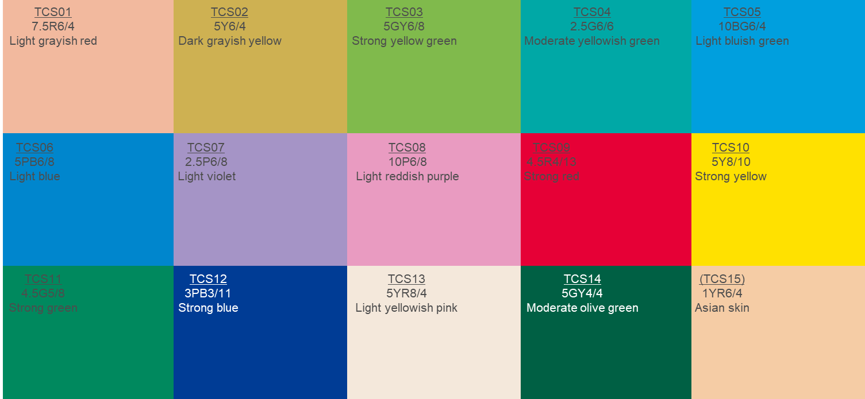

The above standard color cards correspond to R1-R15. Ra is the average value of R1-R8 and R9-R15 are special color rendering indexes. The average value of R1-R15 is called CRI. For LED devices, Ra or CRI can be used to indicate how consistent the light spectrum emitted by the device is with a standard light source. For example, in the field of white LED illumination, R9 represents the light quality for rendering the color strong red, and the light spectrum is more saturated in the red light part if R9 is higher. Under the joint efforts of Beijing Yuji Xinguang Optoelectronic Technology Co., Ltd. and Beijing Nakamura Yuji Technology Co., Ltd., the R12 blue-green portion is supplemented by phosphate blue phosphor, and the R9 part is supplemented by nitride (SCASN) phosphor. Under new packaging process, the R1 ~ R15, Ra and CRI of LED are more than 95 under the excitation by 450-460 nm blue light (without purple light part), achieving true high color rendering with a spectrum extremely close to the daylight spectrum. The development of the violet LED chip and its packaging technology further improves Ra, CRI, R1~R15, which will be the trend of the future market and the heavyweight technical advantages of the Yuji Group.

4. Stability

The stability is essential for LED phosphors and LED devices. Higher stability refers to longer lifespan and thus better practicality and applicability. The stability refers not only to the lifetime of the phosphor and the device, but also to the influence of the environment. Normally, the stability test will be carried out under extreme conditions like high temperature (over 200 °C) and high humidity (over 90%). Among them, the “double 85 tests” (85 °C and 85% humidity) is the most widely used and the most representative method. The product is qualified if after tested under ‘double 85 tests’ for 1000h, its luminous flux is more than 90% of the initial state, and the color coordinate shift is less than 10%. The product is considered superior if its luminous flux is more than 95% and the color coordinate shift is less than 5% after the test. For the MPR series nitride red phosphors and their LED devices from Beijing Nakamura Yuji Technology Co., Ltd., the luminous flux is more than 97% of the initial state and the color coordinate shift is less than 3%, leading the domestic LED phosphor market with the ultra-high performance and stability.