Why High Price For High-quality LED Products? Part – 6

During the last several posts, we’ve analyzed the leading factors of LED lead frames, chips and encapsulants in terms of their qualities and costs. Now, we are moving to the finale of our “high quality LED” series, the LED phosphor.

PRINCIPLES OF LED PHOSPHORS

Most LED phosphors are inorganic photoluminescent powder made of rare earth materials. Under radiance of high energy light, the electrons of the ground state absorb the energy of the exciting light and transit to the excited state of a higher-energy level. The instability of the excited state makes the electron transit back to the ground state in nanosecond time scale. During this process, the excited electrons are accompanied by the radiation of energy, in which a part of the energy is converted into photons and is perceived by us.

From the previous post on LED chips we know that different materials are used to make LEDs of different colors, such as red, yellow, green, blue, purple and so on, and a white LED can be made by mixing several colors of chips. Yet they all have different luminance efficiencies, and even for chips made of a same material, the wavelengths can hardly be adjusted to the same level. Besides, the full width at half maximum (FWHM) of the LED chip is normally quite narrow. This means producing white light by mixing different chips is costly. What’s more, the mixed light is not even close to natural light our eyes are used to, making such an approach totally inefficient.

If we add phosphor to the recipe, a great number of chips will be saved in the first place. Besides, the light will be much softer because the phosphor’s FWHM is wider than the chip’s. So let’s have a look at some of the most commonly used phosphors in the industry.

TYPES OF LED PHOSPHORS

Normally phosphors can be classified by colors, such as green phosphor, orange phosphor and red phosphor. By the type of material they can also be classified as types of YAG, silicate, LuAG, GaYAG, nitride, phosphate and so on. Of course every type has its pros and cons in different application scenarios.

YAG phosphor: YAG phosphors are aluminate compounds that are both physically and chemically stable. They have wide emission FWHM and high brightness. This type is widely adopted because of the mature processing technique and the cheap raw materials. Nonetheless the narrow excitation wave band and spectral lack in the red light give the YAG type LEDs low CRI values.

Silicate phosphor: This type of phosphor has wide tunable emission wavelength but poor chemical stability. It is vulnerable to moisture and high temperature, and has narrow FWHM. These properties confine the application range to small power LED packages.

LuAG phosphor: The LuAG phosphor has stable chemical and thermal properties. With high luminous efficacy and little decay, it can be used together with other types of red phosphors to generate high quality white light. However, the raw materials are expensive and the manufacturing process is highly complex, making this type of phosphor costly.

GaYAG phosphor: GaYAG phosphor is green YAG phosphor containing Ga element. Similar to LuAG, it is chemically and thermally stable with high excitation efficiency and little decay. High CRI white LED can be realized through combination of GaYAG phosphor and other red phosphors. The drawback lies in that it has narrow excitation wave band, which raises the requirements for the LED chip.

Nitride phosphor: Nitride phosphor has stable thermal performance, wide excitation wave band and wide tunable emission wavelength, thus it is commonly adopted in high CRI white LEDs. Just like LuAG phosphor, this type is also expensive due to the high price of the raw materials and the complex manufacturing process.

Phosphate phosphor: This is a blue phosphor normally used in full spectrum white LED together with other types of phosphor. It has limited applications and one of the highest prices owing to its unique characteristics.

3 WAYS TO PRODUCE WHITE LIGHT

Currently there are three common ways to produce white light with phosphors excited by LED chips.

1. Blue chip + yellow (YAG) phosphor

This approach gives the LED high luminous efficacy, but it lacks red light in the spectrum which leads to low color rendering ability. It is usually applied in applications that have lower requirements for light quality.

2. Blue chip + green phosphor + red phosphor

This approach provides lower luminous efficacy than the first one. However, with red phosphor in the recipe, it completes the red part in the spectrum. Showing high color rendering ability, it is widely accepted by the market.

3. Violet chip + blue phosphor + green phosphor + red phosphors

The combination of violet chip and three colors of phosphors has the spectrum closest to natural light, and provides the highest light quality. That being said, large amount of phosphor is used, making the efficacy rather low. This method is applied to produce the most expensive white LEDs, for currently violet chips are much more expensive than blue chips, and the packaging technique is less developed. Applications are limited in certain fields where extremely high light quality is needed.

INFLUENCES OF PHOSPHORS

During the production of an LED, the phosphor is uniformly mixed with encapsulant and applied onto the chip. The phosphor is dominant in the light quality of an LED.

Here are several perspectives from which the light quality can be affected.

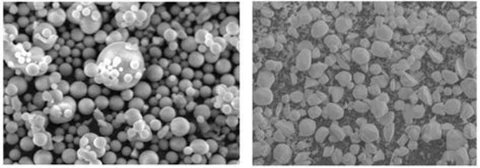

Particle morphology: The particle shape is critical for the LED’s initial luminance output and decay characteristics. As showed in Fig.1 below, spherical phosphor has better dissipation in the encapsulant and can be applied more uniformly. Besides, the phosphor is a surface emitter. That is to say, the less surface defects there are, the higher luminous efficacy it will have. Spherical phosphor has less surface defects, therefore it possesses better initial luminous output.

Particle size: Particle size is the average diameter of phosphor particles, which usually ranges from a few micrometers to a dozen. The phosphor sedimentation during the dispensing process affects the LED’s spectrum characteristic. Larger size particle has greater sediment speed and is more uncontrollable. Another key factor is particle size distribution (PSD), which tells the uniformity of the particles’ sizes. So, in order to produce light sources of high color consistency, the requirements for particle size and PSD are high and strict.

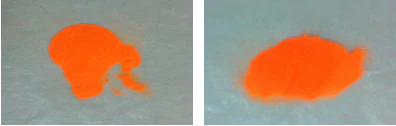

Stability: Stability includes chemical stability, thermal stability and moisture resistance ability. These are all influential in the spectrum change and output decay in use. The stability of the phosphor is determined by the purity of the raw materials, the integration and the processing techniques. Phosphor manufacturers usually add a special process into the whole production procedure so as to increase the stability. Fig. 2 and Fig. 3 show the coating treatment conducted by a Yuji owned phosphor manufacturer. As can be seen, the uncoated phosphor will agglomerate after absorbing moisture, undermine the uniformity of the phosphor and finally decrease the total luminous output. While after treatment of coating, an apparent improvement in moisture resistance can be perceived.

Conclusion

Through this “high quality LED” series on LED lead frames, chips, encapsulants and phosphors, we can see that each part of an LED is critical for the quality of the light source in different ways. The lead frame determines heat dissipation performance, just as the chip does to the brightness, the encapsulant to the sealing performance, and the phosphor to the color quality. Any flaw in any part may cause major performance defect of an LED.

As a provider of high quality LED light source, Yuji LED always applies rigorous standard on material selection and only selects the most suitable materials to ensure the best quality and user experience. We are and always will be devoted to developing high quality light source and providing the ideal light to the market.